I posted on this before, but promised to return to it and get a better tasting syrup. I accomplished the task, here’s the highlights:

Sorghum varieties

I used Sugar Drip last time, this made beautiful looking juice/syrup BUT tasted gamey and unedible. I bought some different ones, 6 altogether but Mennonite was what got planted in quantity. The others were 2-3 plants each for seed for next time. Turns out that Mennonite worked well, the plant is “late maturing” which means it doesn’t make ripe seed until really late in the season (late October). There are lots of others but I have yet to run syrup from them, maybe over the next few seasons I’ll try them but most did not grow too well. I’m hesitant to plant those, to avoid crop failure and a wasted season.

Cane trimming

Here’s some pics of the process. Basically you wait until the seed heads are light or dark brown, cut them off for seed or to mill into flour (soon to happen on this blog). Once the canes are headed, cut a few inches above the ground (that lower part is dry of juice), strip the leaves, and using a knife remove them outer husk. That part is usually dry and moldy, you don’t want it to get into the juice. Cut the canes into pieces small enough to load into the press ( assuming you made one like mine).

The juice press

Press partway, load more until the press is about half full of cane. Then crank down until the juice stops. Remove the waste, repeat. You will need about 4000 PSI on the cane to extract the juice, any less will waste most of it. I don’t see how the roller mills work, you need an incredible amount of force to carry this out and I can’t see how they are effective. Plus they haven’t been made for 100 years, and need a draft animal to operate. It’s not practical to use these for small plots, you need a modern hydraulic press like this one.

I changed the design a bit from last time; the ram goes in the top vs the bottom and attaches via a pipe with 6 set screws. Same setup though. BTW whoever designed the original (an oil press from the 70s) was retarded, it made no sense to have it upside down and to drill that many holes in the body. The liquid only runs out the lower half of the press, so the upper can be solid and you can use maybe half the number of holes. Plus you need a way to easily remove the slug, so I made a plate held by two screws. Easy to pop off and clean. I made a 6×6 square version, but my hydraulic press didn’t have anywhere near the force required. I would have needed 72 tons of force, mine is 12 and only produced a pathetic trickle of juice. I can buy a 50 ton jack, but I’ll need a much heftier frame. We will see, I doubt if I need this much capacity so I might use a 5 inch pipe to keep it realizeable.

Juice settling and pH balance

I found a major source of the foul taste, starch granules. Reading some 1880s literature gave me the clue that I needed to add a base to bind the starch so it forms an insoluble complex and can settle out as a precipitate. The starch burns during the boiling, and it gives the syrup a “strong” taste. Here’s a link to a modern version:

https://www.researchgate.net/profile/Gillian_Eggleston/publication/279184208_Case_Study_Commercialization_of_Sweet_Sorghum_Juice_Clarification_for_Large-Scale_Syrup_Manufacture/links/568ab60e08ae1e63f1fbe6dc/Case-Study-Commercialization-of-Sweet-Sorghum-Juice-Clarification-for-Large-Scale-Syrup-Manufacture.pdf

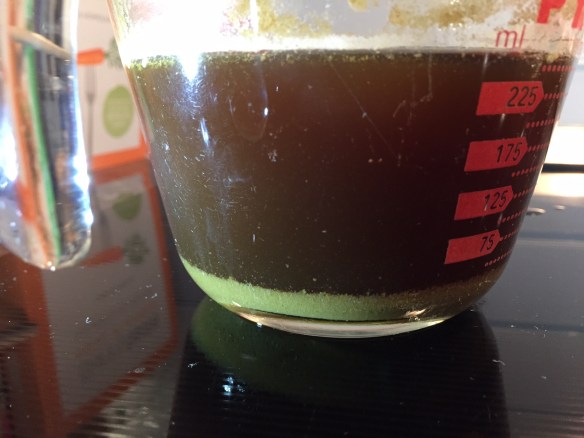

I found I didn’t need to add the carbon, or make up milk of lime per the link, just add small amounts of powdered calcium hydroxide (CaOH) until the pH indicated slightly basic on my swell multicolor litmus papers. I messed up the first batch, I didn’t discover the starch problem until after I boiled it. Note how the raw juice looks like river water:

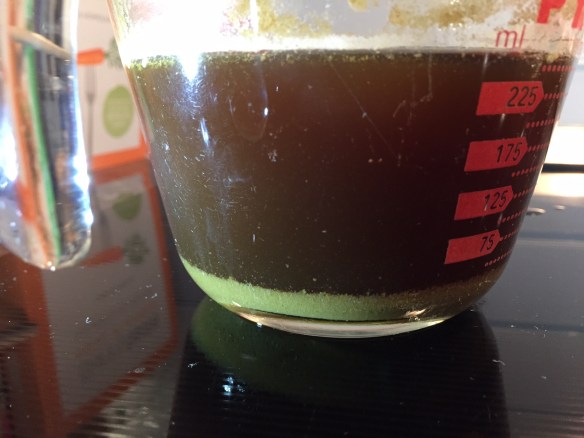

The entire batch was FULL of cloudy crud after boiling, adding the base magically made it fall out:

I was able to pipette the upper layer off, and then ran the bottom part through our old friend the coffee filters to do the rest. It wasn’t the right way to do it, but it worked. I had about 15 plants left that were too green to harvest, when those were ready I followed the procedure and added CaOH (lime) to the raw juice:

This is what I’m talking about, Willis! The starch all came out and I easily drew off the supernate, and it boiled off to a nice clear syrup. Well, clear but dark like differential oil. That’s a consequence of the base, it darkens the syrup but is essential for taste. As for that, it is now edible but still not close to corn syrup. I had some on pancakes, I could eat them but would not want a lot of it. I think it would be best in some baked goods, like cookies or bread. I will try different varieties of sorghum to see if I can get it a bit lighter, it’s plenty sweet but has that funky note. But way better than the first batch. BTW this stuff is very molasses-like, not as strong but isn’t something modern people use a lot of.

Finally, I noticed the syrup is runny even though I cooked it down to 240 F on the candy thermometer. The old timers say 228 is the end point, but I’m not convinced. I’ve seen vague references to runniness on line, but I have no clue.